Description

The thinning of trees in either even- or uneven-aged stands involving removal of trees in rows, strips, or by using fixed spacing intervals (Adams et al. 1994).

Extent

Geometric thinning is the most common method of applying the first thinning to plantation forests, due to its simplicity, effectiveness, and efficiency. It can also be applied in naturally regenerated stands, although this is not as common an application.

Application

Common Variations

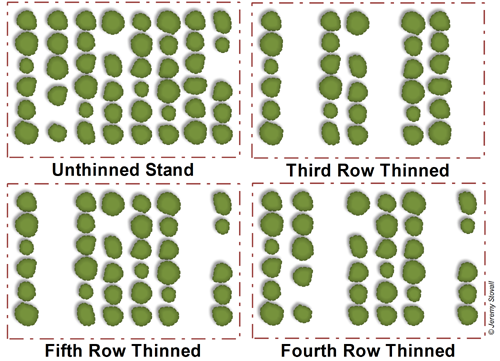

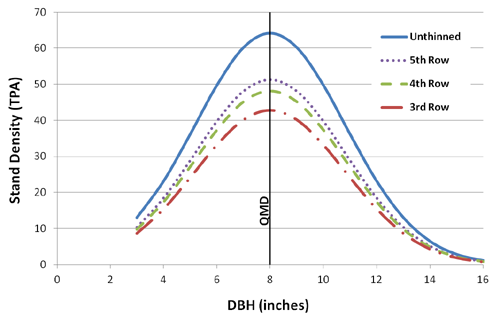

Geometric thinning is commonly referred to as mechanical thinning since it is usually accomplished with mechanized equipment such as shears or fellers. The most common application of geometric thinning is row thinning. Because plantations are established in rows, it is practical to remove every 3rd, 4th, or 5th row to reduce basal area by 33%, 25%, or 20%, as desired.

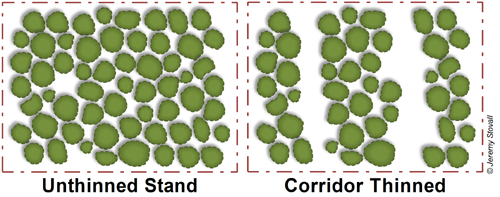

In naturally regenerated stands trees are not planted in rows. It is still possible to geometrically thin natural stands by creating downed corridors. These corridors should be specified in terms of their width, and the width between their centers to ensure that the correct percentage of the stand is removed in the harvest. Felling 15-foot-wide corridors spaced every 60 feet on center would be comparable to a fourth row thinning of a plantation.

Ecological Consideration (Silvics)

Because trees are randomly selected in a geometric thinning based on nothing more than their location within the stand, there is no change in the stand's quadratic mean diameter (QMD) due to thinning. For example, in a 3rd row thinning 33% of the smaller trees, 33% of the average-sized trees, and 33% of the larger trees will all be removed. The d/D ratio, which is the QMD of trees removed divided by the pre-thinned stand QMD, will thus always be 1.00 for any geometric thinning. Stand density (TPA) and basal area will be reduced by whatever proportion of trees are removed. If the pre-thinned stand had 450 trees per acre and a basal area of 120 ft2 per acre, then following a third row thinning the stand will have 300 trees per acre and 80 ft2 per acre.

As with any method of thinning, geometric thinning allocates more site resources to the crop trees that are retained, resulting in deeper crowns with greater leaf area per tree (Medhurst and Beadle 2001). Individual trees have more photosynthate and grow at a faster rate following thinning. Row thinning tends to result in less of a growth response that is allocated more to smaller diameter trees compared to low thinning, although this effect varies in magnitude by species (Baldwin et al. 1989).

There are benefits to thinning beyond increased growth rates. In southern pines early row thinning to limit stocking can be an effective means of minimizing the risk of insect attacks by species such as the southern pine beetle (Burkhart et al. 1986, Nebeker and Hodges 1983).

Economic Considerations

Certain minimum requirements must be met for a thinning operation to be merchantable. A thinning is deemed merchantable when revenue to the landowner equals or exceeds costs incurred to have the stand thinned. For first thinnings in pine plantations, this usually requires a stand of at least 20 acres with a basal area of about 100 ft2 per acre and a QMD of 6.5 inches (Harrington 2001). The QMD must be sufficient since there is a minimum merchantable diameter for pulpwood. The basal area must be enough that the stand will show a growth response to the thinning. If these criteria are met, it will result in 15 to 25 tons per acre being removed from the stand. If the stand is closer to the mill or timber prices are higher less must be removed per acre to make an operation merchantable.

Geometric thinning requires less effort than other methods of thinning that remove the same volume due to its higher operational efficiency (Lemmien and Rudolph 1964). This results in lower costs for thinning. Harvesters tend to operate more efficiently on older stands compared to younger stands, on better sites compared to poorer sites, and on stands with lower densities compared to stands with higher densities (Granskog and Anderson 1980).

In some regions, it is becoming an increasingly common practice to chip trees in the woods to produce material for fuel-wood in biomass energy plants or for cogeneration in traditional mills. This practice allows smaller diameter trees (e.g. < 5 inches in diameter) or trees that are otherwise unmerchantable to be utilized in a cost-effective manner (Mitchell and Gallagher 2007). Whether this practice will become more commonplace depends on the economic viability of biomass energy markets.

Societal Considerations

Row thinning can be popular among hunters leasing forest land, as it creates long, clear shooting lanes. If competition is not controlled in the downed rows, herbaceous and shrubby vegetation with some wildlife food and habitat value will often establish. Row thinning has been shown to increase the biomass and diversity of the herbaceous strata, more closely mimicking naturally regenerated stands later in succession (Ishii et al. 2008).

There can be visual quality issues associated with row thinning, although not to the same extent as clearcutting. If downed rows are oriented perpendicular to highways or roads they will be noticeable to the public. It is possible to avoid this effect through several different modifications. If possible, rows can be oriented parallel, rather than perpendicular to roads. Even if the rows are perpendicular to the roads, an aesthetic management zone several trees wide can be left along the road to avoid site-lines down the rows. In plantations established today it is common to plant trees along the contours rather than in geometrically precise straight lines. This usually results in undulating rows which do not create long sight-lines following row thinning.

Silvicultural System Considerations

Geometric thinning will result in trafficking of heavy equipment over a significant percentage of the area of a stand. In a third-row thin, this area may be as high as 40%, with rutting caused on up to 15% of the area if operations are conducted on sensitive soils during wet weather (Karr et al. 1987). Precautions should be taken to ensure no rutting or compaction occurs, as it will not be possible to ameliorate these effects with site preparation until the end of the rotation. Thinning operations should be conducted when soils are dry. In colder regions they can be conducted in winter when the ground is frozen to minimize any impact on the soil.

Because row thinning is easy to implement in the field, it requires little timber marking other than property boundaries and any areas that should not be thinned. Since the operator is selecting the rows that are being removed, this is commonly referred to as an 'operator-select' operation. Operators working for large forest products companies are routinely checked by foresters who install plots in thinned areas to ensure their prescription is being followed. Adjustments are made accordingly based on their data. Frequent assessment is often necessary because row thinning is commonly combined with removing poorly formed or small trees in the rows that are to be left. This practice is covered in more detail in the free thinning section.

Basal area is a common metric of stand density used to prescribe thinning intensity. For loblolly pine plantations stands are commonly thinned when they reach 100-120 ft2 per acre or more. Basal area is typically reduced to 70-80 ft2 per acre at each thinning entry. For naturally managed stands, it is possible to reach basal areas above 120 ft2 per acre before thinning, and to thin down to a higher basal area. Basal area targets will vary by species, region, and objectives. See the quantitative silviculture sections for more details.

Other Intermediate Treatments

In general geometric thinning is more commonly applied as the first thinning in a rotation. It is difficult to apply a row thinning twice because the space between remaining rows will eventually become too large for the crowns to close over. Row thinning later in a rotation also may remove too many valuable, large-diameter crop trees that would better be left until the end of the rotation. Often a row thinning is followed by a low thin.

Timing other intermediate treatments such as competition control and fertilizer application with a thinning may result in improved growth responses over thinning alone. Competition control will prevent allocation of site resources to non-crop species growing in the newly cleared rows. Fertilizer application will increase leaf area, ensuring that the newly released trees develop deeper crowns. Interactions between thinning and these intermediate treatments is covered in greater detail in the sections on each.

Establishment Treatments

Initial planting density and spacing plays an important role in determining the timing and method of later thinning operations (Schönau and Coetzee 1989). Greater planting densities tend to produce stands have greater total yields. However, this also results in a lower mean diameter, as each tree has access to fewer resources, and thus lower total merchantable yields. These stands will require longer to grow to the point that they are merchantable to thin due to the effect of density on diameter. Stands planted at lower initial densities may produce less total volume, but over the rotation a greater proportion of it will be merchantable material. These stands can be thinned sooner in the rotation, because they reach the minimum required diameter quicker as each tree has access to more site resources.

These relationships are also affected by site quality. On better quality sites, increasing density past a certain point results in sawlog yields that eventually stabilize at a fairly consistent level. By contrast, on poorer sites greater densities actually reduce sawlog volume at the end of the rotation because site resources are too limiting to produce trees with sufficiently large diameters (Stiff and Stansfield 2004).

Densities of loblolly pine plantations in the US South were historically higher than they are now. Planting densities have been reduced over time as pulpwood prices have fallen and silvicultural inputs have been intensified. Current average planting densities across the south are slightly less than 500 trees per acre (Barlow and Dubois 2011).

Greater between-row spacing results in increased operator efficiency in terms of wood volume removed per hour (Granskog and Anderson 1980), and in less fuel consumed per acre treated. While advantageous to a point, if spacing becomes too rectangular it may be impractical to apply a row thinning because it will leave unused growing space between rows. The tighter within-row spacing required at wider between-row spacings may also make it challenging to remove trees in leave rows without damaging residuals in a row plus operator select thin. Wider between row spacing at planting does not affect survival, growth, volume production, or stem form, up to a within-row:between-row ratio of 1:3 (Amateis et al. 2004, Sharma et al. 2002). However, more rectangular spacing does tend to result in trees with larger branches and wider crowns (Amateis et al. 2004, Sharma et al. 2002).

Regeneration Treatments

Thinnings must be planned with a knowledge of the desired rotation length. Thinning too close to a regeneration treatment will not allow the residual trees to fully expand their crowns and grow sufficiently to make the thinning an advisable treatment. Usually stands are not thinned within 5-10 years of final harvest, depending on species, region, and site quality. A detailed financial analysis such as that found in Stiff and Stansfield (2004) can guide the selection of thinning timing and rotation length selection depending on site quality and management objectives.

Pros

- Operationally efficient

- Requires little effort in marking

- Limited damage to residual stand

- Improves value of stand for wildlife (habitat, food, shooting lanes)

Cons

- Removes potential crop trees

- Results in less of a growth response than other thinning methods

- Allocates growth preferentially to smaller trees

- May be aesthetically unpleasing near roads

Examples

Figure 5.7.12. A geometric thin performed by manually removing every other row in a Populus spp. plantation in Idaho. Photo Credit: Chris Schnepf, University of Idaho, Bugwood.org

Figure 5.7.13. A feller-buncher implementing a geometric thin by cutting 16-foot-wide corridors in a boreal mixed-species stand to emulate natural disturbances in Northwestern Alberta, Canada. Photo Credit: David Shorthouse, University of Alberta,Bugwood.org

Figure 5.7.14. A row-thinned sweetgum plantation in Florida. Photo Credit: Brian Lockhart, USDA Forest Service, Bugwood.org

Figure 5.7.15. A row-thinned yellow-poplar plantation in Mississippi. Photo Credit: Brian Lockhart, USDA Forest Service, Bugwood.org

Figure 5.7.16. A fifth-row thinned a loblolly pine plantation. Photo Credit: James Miller, USDA Forest Service, Bugwood.org

Figure 5.7.17. A geometric thin performed by cutting 20-foot-wide corridors into a midrotation bottomland hardwood stand in East Texas. In addition to improving growth of the remaining crop trees, the corridors will be planted in Rubus and managed as bear habitat. Photo Credit: Jeremy Stovall

References

Adams, D. L., J. D. Hodges, D. L. Loftis, J. N. Long, R. S. Seymour, and J. A. Helms. 1994. Silviculture Terminology with Appendix of Draft Ecosystem Management Terms. Silviculture Instructors Subgroup of the Silviculture Working Group of the Society of American Foresters. https://www.silvicultureinstructors.com/index.php/resources/silviculture-terminology

Amateis, R. L., P. J. Radtke, and G. D. Hansen. 2004. The effect of spacing rectangularity on stem quality in loblolly pine plantations. Canadian Journal of Forest Research 34:498-501. http://dx.doi.org/10.1139/x03-210

Baldwin Jr, V. C., D. P. Feduccia, and J. D. Haywood. 1989. Postthinning growth and yield of row-thinned and selectively thinned loblolly and slash pine plantations. Canadian Journal of Forest Research 19:247-256. http://dx.doi.org/10.1139/x89-035

Barlow, R. J. and M. R. Dubois. 2011. Cost and cost trends for forestry practices in the south. Forest Landowner 7:14-24. http://www.forestlandowners.com/

Burkhart, H. E., H. L. Haney, J. D. Newberry, W. A. Leuschner, C. L. Morris, and D. D. Reed. 1986. Evaluation of thinning for reduction of losses from southern pine beetle attack in loblolly pine stands. Southern Journal of Applied Forestry 10:105-108. https://doi.org/10.1093/sjaf/10.2.105

Granskog, J. E. and W. C. Anderson. 1980. Harvester productivity for row thinning loblolly pine plantations. Res. Pap. SO-163. New Orleans, LA: U.S. Department of Agriculture, Forest Service, Southern Forest Experiment Station. http://www.srs.fs.usda.gov/pubs/20652

Harrington, T. B. 2001. Silvicultural approaches for thinning southern pines: Method, intensity, and timing. Georgia Forestry Commission Publication No. FSP002.

Ishii, H., M. Maleque, and S. Taniguchi. 2008. Line thinning promotes stand growth and understory diversity in Japanese cedar (Cryptomeria japonica D. Don) plantations. Journal of Forest Research 13:73-78. http://dx.doi.org/10.1007/s10310-007-0051-7

Nebeker, T. E. and J. D. Hodges. 1983. Influence of forestry practices on host-susceptibility to bark beetles. Zeitschrift für Angewandte Entomologie 96:194-208. http://dx.doi.org/10.1111/j.1439-0418.1983.tb03660.x

Karr, B. L., J. D. Hodges, and T. E. Nebeker. 1987. The effect of thinning methods on soil physical properties in north-central Mississippi. Southern Journal of Applied Forestry 11:110-112. https://doi.org/10.1093/sjaf/11.2.110

Lemmien, W. A. and V. J. Rudolph. 1964. Economic and silvicultural aspects of row and basal area thinning planted red pine. Journal of Forestry 62:721-723. https://academic.oup.com/jof/article-abstract/62/10/721/4672170

Medhurst, J. L. and C. L. Beadle. 2001. Crown structure and leaf area index development in thinned and unthinned Eucalyptus nitens plantations. Tree Physiology 21:989-999. http://dx.doi.org/10.1093/treephys/21.12-13.989

Mitchell, D. and T. Gallagher. 2007. Chipping whole trees for Fuel chips: A production study. Southern Journal of Applied Forestry 31:176-180. https://doi.org/10.1093/sjaf/31.4.176

Schönau, A. P. G. and J. Coetzee. 1989. Initial spacing, stand density and thinning in eucalypt plantations. Forest Ecology and Management 29:245-266. http://dx.doi.org/10.1016/0378-1127(89)90097-2

Sharma, M., H. E. Burkhart, and R. L. Amateis. 2002. Spacing rectangularity effect on the growth of loblolly pine plantations. Canadian Journal of Forest Research 32:1451-1459. http://dx.doi.org/10.1139/x02-079

Stiff, C. T. and W. F. Stansfield. 2004. Thinning guidelines for loblolly pine plantations in eastern Texas based on alternative management criteria. Pages 323-329 in Proceedings of the 12th biennial southern silvicultural research conference. Gen. Tech. Rep. SRS71. Asheville, NC: U.S. Department of Agriculture, Forest Service, Southern Research Station. http://www.treesearch.fs.fed.us/pubs/6682